22 MM 2-STRIP SOLID HARDWOOD FLOORING

PRODUCT INFORMATION

B 2.0

PRODUCT SPECIFICATION

Junckers 22 mm 2-strip solid hardwood floors are factory finished and ready to install in accordance to Junckers Laying Instructions.

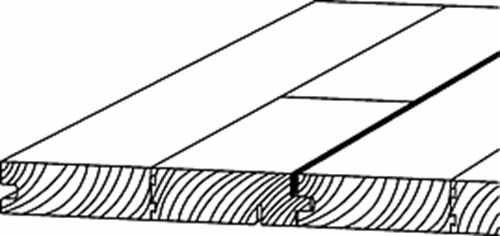

Each floorboard is assembled from two rows of staves by a glued double dovetail construction.

Each floorboard is tongued and grooved on all four sides.

PRODUCT DATA / TOLERANCES

Nominal Board Dimensions

Thickness: 21.8 mm (±0.2 mm)

Width: 129.0 mm (±0.2 mm)

Length Commercial/Residential floors:

3700 / 1830 / 900 mm (±1.0 mm)

Length Sports floors:

3700 mm (±1.0 mm)

Drying Method

Beech, all variants: Press dried.

Maple, Oak and Ash, all variants:

Kiln dried.

Average Moisture Content, MC

Beech, Maple, Oak and Ash (all variants except Black Oak): 8 % (±2 %).

Black Oak: 9 % (±2 %)

NH3 treatment of Black Oak and Beech Sylvaket/Sylvared means that MC can´t be measured by using a conventional moisture meter but must be measured by the “dry weight method”.

Precision Engineering

Landing Deviation: 0.2 mm

(0.3 mm in localised areas).

Board ends are right angled at ±0.3 mm.

PRODUCT RANGE, COMMERCIAL / RESIDENTIAL

|

Product |

Grade |

Surface |

Product variants |

|

Beech |

Classic |

Ultra matt lacquered |

Ships decking* |

|

Beech SylvaRed |

Classic |

Ultra matt lacquered |

Ships decking* |

|

Ash Nordic |

Classic |

White pigmented and |

Ships decking* |

|

Black Oak |

Harmony |

Ultra matt lacquered |

Ships decking* |

|

Maple |

Classic |

Ultra matt lacquered |

Ships decking* |

|

Oak Pearl |

Harmony |

Metallic-pigmented and |

Ships decking* |

*See Fig. 1

**See possibilities in current Product selector.

Fig. 1

SHIPSDECKING

Strip made of foamed PVC with closed cells to absorb natural movements in the hardwood floor. The strip measures 3x8 mm and installed it provides a 2 mm wide joint, which varies over the year according to changes in the relative humidity.

PRODUCT RANGE, SPORT

|

Product |

Grade |

Surface |

|

Beech SylvaSport |

Champion |

Ultra matt lacquered |

|

Maple |

Champion |

Ultra matt lacquered |

|

Sylva Squash: |

Champion |

Silk matt lacquered |

TECHNICAL PROPERTIES

Resistance to Indentation

Oak, ash, maple (all variants): Approx. 3.4 Hardness Brinell

Beech (all variants): Approx. 3.7 Hardness Brinell

Slip Resistance, (preliminary):

Lacquered: Approx. 0.4 (DIN 18032/2) and Approx. 85 (EN 14904)

Oiled: Approx. 0.4 (DIN 18032/2)

Fire Classification, (DIN EN 13501-1):

Surface treated: Cfl – S1

Untreated surface: Dfl – S1

Thermal Conduction, (Transmission coefficient):

Approx. 0.17 W/mK

Heat Resistance: Approx. 0.13 m2 K/W

Electrostatic Charging (kV), Beech:

Factory lacquered:

25% RH = 3.5

50% RH = 2.0

65% RH = 1.0

Factory oiled:

25% RH = 1.0

Oiled Beech is suitable for use in rooms with computers. (DIN 54345/1-prEN 1815)

|

Light reflection value (LRV) |

||

|

|

Ultramatt |

Silkmatt |

|

Ash |

- |

49 |

Substances of very high Concern

The products do not contain substances from the REACH Candidate List, ”Candidate List of Substances of Very High Concern for Authorization, whose content exceeds 0.1 weight percent.

FACTORY SURFACE TREATMENT

LACQUERED

Beech, Beech SylvaSport, Oak, Ash & Maple:

Priming: Several coats of UV-light curing primer.

Top finish: Two-component polyurethane lacquer, silk/ultra matt.

Total film thickness: Min. 40 µ.

Beech SylvaKet and SylvaRed:

Pre-treatment: Coloured throughout with a NH3-treatment to achieve a light brown colour.

Before lacquering Beech SylvaRed is also toned with a reddish stain. If Beech SylvaRed is sanded to bare wood, it will appear like Beech SylvaKet.

Priming: Several coats of UV-light curing primer.

Top finish: Two-component polyurethane lacquer, silk- or ultra matt.

Total film thickness: Min. 40 µ.

Oak Pearl:

Priming: Water based transparent stain.

Intermediate treatment: Several coats of UV-light curing lacquer.

Top finish: Two-component polyurethane lacquer, ultra matt.

Total film thickness: Min. 40 µ.

Black Oak:

Pre-treatment: Coloured throughout with a NH3-treatment to achieve a dark brown colour.

Intermediate treatment: Several coats of UV-light curing lacquer.

Top finish: Two-component polyurethane lacquer, ultra matt.

Total film thickness: Min. 40 µ.

Other colours:

Priming: Coloured stain.

Intermediate treatment: Several coats of UV-light curing lacquer.

Top finish: Two-component polyurethane lacquer, ultra matt.

Total film thickness: Min. 40 µ.

OILED

Priming: Surface saturation using oxidative drying urethane oil.

Top finish: Oxidative drying urethane oil.

Total oil consumption: Addition to a full surface saturation.

UNTREATED: Final sanding to grit 150.

SQUASH

Untreated: Final sanding to grit 40.

Lacquered: Final sanding to grit 40 + 1 coat of a silk matt two-component polyurethane lacquer.

PACKING AND WEIGHT

Board length 3700 mm: Wrapped in LDPE plastic.

Board length 1830 and 900 mm: Wrapped in LDPE plastic and cardboard.

Boards per pack / Length / m2

4 floorboards / 3700 mm / 1.91 m2

3 floorboards / 3700 mm / 1.43 m

8 floorboards / 1830 mm / 1.89 m2

6 floorboards / 1830 mm / 1.42 m2

8 floorboards / 900 mm / 0,93 m2

One layer in packs of 1830 mm length may consist of two floor boards of 900 mm.

Weight kg/m2

Beech (all variants): 16.35 kg

Oak (all variants): 15.50 kg

Ash (all variants): 14.50 kg

Maple: 14.5 kg